PARS2.0

A computational software for Performance analysis of the fuel Rod in steady state

INTRODUCTION

Fuel rods are the source of heat generation in nuclear reactors as a result of nuclear fission chain reaction which lead to series of complex changes including the behavior of pellet, cladding, gap, and mechanical interaction between pellet and cladding (PCMI). In order to performance analysis of fuel rods, various computational codes were developed by different countries.

PARS has been developed by the I. R. Iran’s Advanced Nuclear Computing Center (ANCC) to cover this demand.

PARS2.0 software deals with performance analysis of fuel rods in steady state conditions. This code has the ability to simulate Uo2 fuel rods of solid type or with central hole (as in WWERs). Clads composed of Zr2, Zr4, Zr+1%Nb can also be taken into account. The PARS2.0 software is applicable to model the fuel rods of PWR, BWR, WWER and HWR reactors. It is also useful for long term analysis of fuel performance in multi-year cycles as the changes are rather slow, and the working condition can be assumed steady state. As a result, different irradiation intervals can be modeled under the assumption of stable condition.

METHODOLOGY

Almost all models and methods of PARS2.0 code are based on FRAPCON3.4 US NRC code that are as follows:

-

-

- Enthalpy rising model for coolant condition in axial direction;

- IF-97 library for water properties;

- TRANSURANUS Burnup Model (TUBRNP) for radial power profile in fuel pellets;

- Finite difference method for thermal analysis of the fuel rod;

- Ross and Stoute model for gap heat transfer coefficient;

- Control volume and energy balance for Upper plenum gas temperature calculation;

- FRACAS-I model for pellet and cladding mechanical interaction analysis;

- Free-ring expansion model for radial deformation of the pellet;

- Modified Forsberg and Massih model as a default model for fission gas release;

- Perfect gas law for rod internal gas pressure;

- GT2R2 model for relocation.

-

PARS2.0 code has been equipped with a set of computation models including axial coolant parameters, radial power distribution, and fuel and cladding temperature distribution, cladding elastic & plastic stress and strain analysis in hoop and axial direction, fission gas release, corrosion, hydrogen pick up and cladding creep.

FEATURES

Followings are the major capabilities of PARS2.0 software:

- Thermal & mechanical analysis of the fuel rod based on finite difference method.

- Western PWR, Russian VVER, BWR and HWR fuel rods modeling capability.

- Square, triangle and favorite lattice are included.

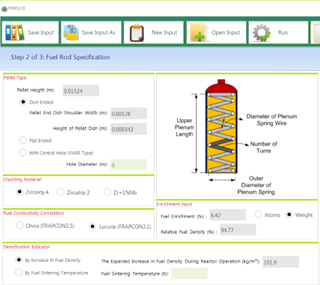

- Flat ended pellet and dish ended pellet and Pellet with Central Hole (VVER type) are selectable.

APPLICATIONS

PARS2.0 is especially developed for fallows purposes:

- PWR, VVER and HWR fuel rod performance analysis,

- Input data preparation for Transient fuel rod performance analysis (PART code).

The software covers a wide range of needs for students, researchers and engineers in design and performance analysis of fuel rods. Input parameters definition can be simply carried out easily by graphical user interface of PARS2.0 software, for example: Fuel pellet specification; Cladding material; Upper plenum spring dimension; Active fuel length and channel parameter and etc.

The user can plot main parameters during time or burnup. An interesting feature proposed for PARS 2.0 is the ability to display animated selected results during the time.